#Industry News

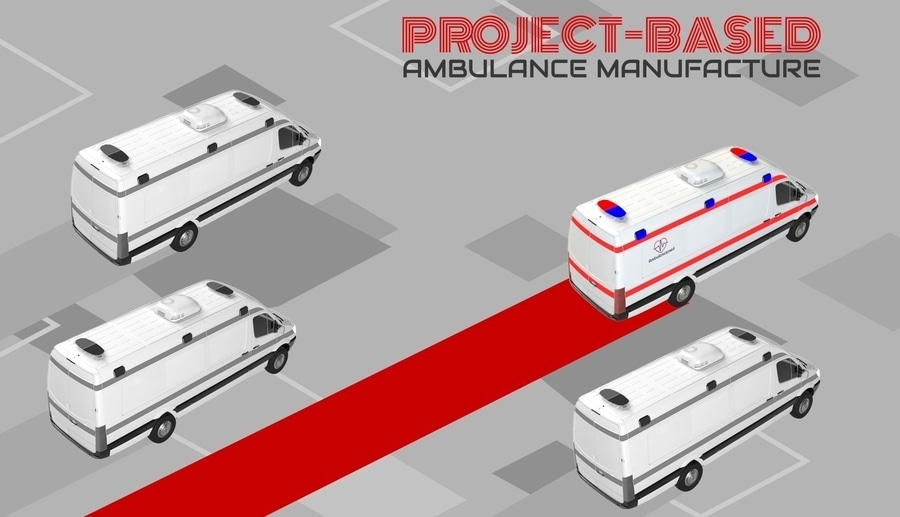

YOUR PROJECT-ORIENTED CUSTOMIZED MANUFACTURER

Our competitive advantage

Welcome to the future of ambulance manufacturing. At our company, we specialize in project-based ambulance manufacturing, where every vehicle is uniquely designed and built to meet the specific needs of our clients. Project-based manufacturing is revolutionizing an industry where precision, speed, and customization are paramount. With this innovative approach, we focus on quality and short lead times, setting a new standard for producing ambulances tailored to every customer's needs. Here's how our project-based ambulance manufacturing process works:

Advantages of Project-Based Manufacture:

As the main idea, project-based manufacturing allows for faster turnaround times and reduced costs. With a focus on individual projects, manufacturers can optimize their processes and reduce waste, resulting in lower production costs and shorter lead times. This means that customers can receive their ambulances in shorter times compared to the mass producers.

Project-based manufacturing offers a tailored approach that goes beyond standard ambulance production. By creating custom solutions outside of the standards, manufacturers can meet specific customer requirements with precision and efficiency. This flexibility allows for the integration of special medical equipment seamlessly into the design, ensuring high quality and compatibility with the end product.

Moreover, project-based manufacturing enables closer collaboration between manufacturers and customers, resulting in a more personalized experience. This direct communication streamlines the process and minimizes errors by addressing any concerns or modifications promptly. With a focus on innovation and adaptability, this approach sets a new benchmark for excellence in ambulance manufacturing.

Focus on the Quality:

When it comes to project-based ambulance manufacturing, focusing on quality is paramount. Our team of experts carefully sources and selects the best materials to ensure durability, safety, and reliability. Additionally, our manufacturing process follows strict quality control measures to guarantee that each vehicle meets the highest standards. Every component and aspect of the ambulance must meet high standards to ensure reliability and safety during emergencies. From the specialized medical equipment to the construction materials used, attention to detail in quality control is key.

High-quality materials are non-negotiable when it comes to manufacturing ambulances that can withstand rigorous use and provide optimal care for patients. By prioritizing quality, manufacturers can guarantee that their products will meet customer requirements and exceed expectations. This is especially important in the medical field, where reliability is crucial in saving lives. In conclusion, project-based ambulance manufacturing is the future of the industry, offering a customized and efficient approach to producing high-quality vehicles. With a focus on quality, collaboration, and innovation, this method sets a new standard for excellence in ambulance manufacturing.

Short Lead Time:

Moreover, project-based manufacturing has the advantage of short lead times. By focusing on individual projects, manufacturers can optimize their processes and reduce waste, resulting in shorter production times. Due to this, customers can receive ambulances more quickly than mass producers.

When it comes to ambulance manufacture, time is a key element to consider. Project-based manufacturing allows for a streamlined production process that ensures quick turnaround times without compromising quality. By focusing on customer requirements and utilizing special medical equipment outside of the standards, manufacturers can efficiently produce ambulances tailored to specific needs in record time.