#Industry News

Revolutionary Cleaning System for Reusable Medical Device using sodium bicarbonate

98% of effectiveness in pre-washing all complex instruments without abrasion

The pre-treatment of reusable medical devices (RMD) is a fundamental step to maximize the effectiveness of the entire sterilization cycle.

The washing phase follows the pre-treatment, which aims to eliminate the contamination from RMD bringing it to the level of <3μg / cm² required by the EN 15883-5 standard.

The persistence of organic matter residues on the RMD can lead to the survival of microorganisms within the biofilm, causing a risk for the patient.

RMD are often characterized by considerable differences in terms of geometry, materials, structure, resistance to reprocessing, degree of initial contamination and level of quality of the final reprocessing obtained. In case of critical instruments to be cleaned and adhered contaminants, the traditional washing processes may be insufficient and it is forced to apply to manual pre-washing remedies injurious for the devices and dangerous for the operators (brushing, solvents, treatments with abrasive pastes , air-steam), not always effective.

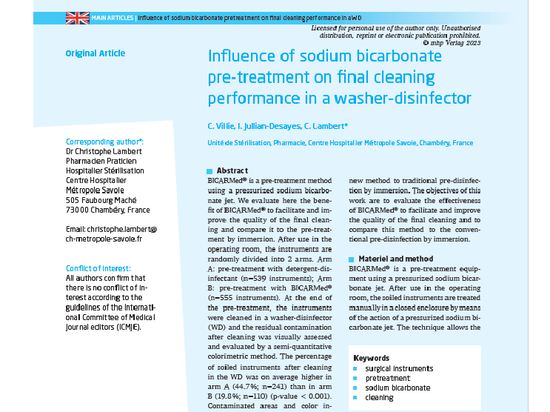

A study carried out by Prof C. Lambert inside the sterilization unit in Chambéry (F), confirms the persistence of dirt after cleaning with the washer disinfector and thermodisinfection. Among the instruments examined, the most contaminated come from some departments in particular: gynecology, dentistry, otolaryngology, visceral surgery and orthopedics.

The study compared traditional pre-washing methods with the new BICARmed ® treatment with SAFEKlinic®, a particular compound of sodium bicarbonate in granules, conveyed with low-pressure compressed air and water.

The results of the research have shown that repeated and systematic use during each reprocessing cycle with BICARmed ® technology brings significant improvements in cleaning the dirty RMD.

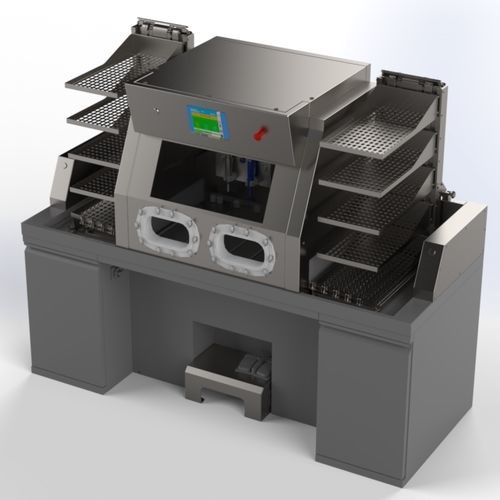

BICARmed technology allows to pre-treat the RMD through a jet of sodium bicarbonate and pressurized water inside a closed cabin. The non-toxicity of sodium bicarbonate and the isolation of the work area that prevents contact with dangerous contaminants guarantees maximum safety for the operator.

BICARmed treatment accuracy derives from the constant and continuous action of the sodium bicarbonate: projected on the surface, bicarbonate is capable to hit the same point repeatedly and continuously over and over again.

This action makes the BICARmed process comparable to a highly efficient mechanical brushing. Simulations show that one second of treatment with the BICARmed ® process is equivalent to 40 seconds of manual brushing. In addition to this there is the advantage of being able to treat and remove any type of contaminant from any type of reusable surgical instrument.

Furthermore,the special granulometry of SafeKlinic® bicarbonate, specifically studied to reduce dustiness to a minimum, allows to treat cavities less than 100 µ with great effectiveness and accuracy and to flush all cannulated instruments maintaining their patency and thus avoiding the risk of obstruction

The mechanical action of the granules has no abrasive effects: the kinetic energy is absorbed by the granule itself which, after the impact with the surfaces to be cleaned, is destroyed.

SAFEKlinic sodium bicarbonate is noncorrosive, completely soluble, and biodegradable. Therefore, it does not pollute the environment and it is safe for operators.

BICARmed Treatment Advantage:

• EFFECTIVENESS: FULL CONTAMINANTS AND PROTEINS-BIOFILM REMOVAL

Maximum removal of difficult compounds like dirt, bone, cement, cauterized blood, even on geometrically complex surfaces.

• NON–ABRASIVE AND NON-CORROSIVE

The treatment does not damage the protection of the instruments and is performed into a closed cabin thus avoiding operator contact with dangerous contaminants.

• LESS MAINTENANCE AND REPLACEMENT COSTS

BICARmed treatment cleans instruments in-depth and removes the biofilm, extending the life cycle of instruments and reducing maintenance costs.

An effective cleaning prevents the accumulation of debris deposits on the instruments’ surface, thus reducing instrument damage from oxidation. Oxidation creates micro holes on RMD surfaces over time (pitting), of difficult, if not impossible, cleanliness, which weakens instruments leading them to early breakage. Therefore, preventing oxidation will extend the average lifespan of RMD.

• WATER AND CHEMICALS SAVING

• CLEANING TIME-SAVING

One way to pre-washing all instruments: endoscopic optics, motor drills, canulas, fragile instruments, and generic and specialized instruments.

• EASY TO USE AND SAFE FOR THE OPERATOR

The treatment is performed into a closed cabin thus avoiding operator contact with dangerous contaminants.

• ECOFRIENDLY: 100% BIODEGRADABLE AND WATER SOLUBLE