#Industry News

ICH-compliant photostability tests in just two days

BINDER presents its modular photostability test chambers

With its new modular photostability test chambers, BINDER GmbH is expanding its product portfolio for tailored solutions for photostability tests in accordance with the ICH guideline Q1B. The new units combine state-of-the-art environmental simulation technology with a modular design that allows them to be adapted individually to specific requirements and test parameters. They can be used to carry out a complete ICH-compliant photostability test in just two days.

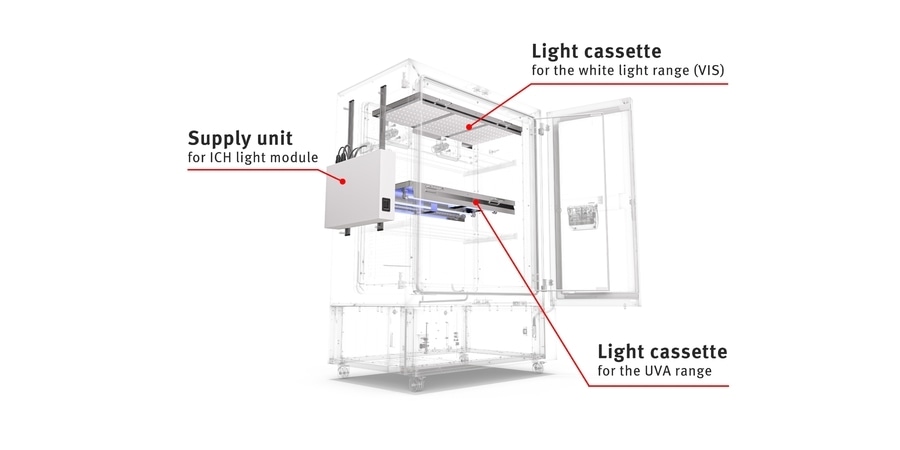

Climate chamber + ICH light module = photostability test chamber

BINDER has put a great deal of work into developing a product line that offers customers maximum flexibility. This is achieved thanks to the modular design of the photostability test chambers, which makes it possible to configure a customized unit. The ICH light modules can be mounted quickly and easily and convert the chosen base unit into a photostability test chamber. Thanks to the unique modular principle, the chambers can be expanded or converted as required, which means they can be used for a wide range of different applications.

Each ICH light module consists of a control unit, which is fastened to the prepared unit side wall, and two illumination cassettes – one for the white light range (VIS) and one for the UVA range. The light qualities are proven to fulfill the requirements of the ICH guideline Q1B. The irradiance and illumination levels of the BINDER ICH light modules are designed so that a complete ICH photostability test can be carried out in two days. The climate control in the chamber ensures that the preset climate is maintained at all times despite the high light intensity.

Cost-effective thanks to maximum flexibility

The new units save not just time, but also space and money. The modular design means that it is possible to carry out stability tests according to ICH Q1A and ICH Q1B with a single unit. This significantly reduces the amount of space required in the laboratory as well as the investment and operating costs. The climate chambers can be retrofitted with an ICH light module at any time in order to adapt to changing requirements.

Further time and cost savings can be achieved in the event of microbial contamination, as the automatic 100°C disinfection routine eliminates the need for time-consuming manual disinfection.

The new photostability test chambers also deliver when it comes to sustainability and energy efficiency. They consume 40 percent less energy than their predecessors and are operated with the natural refrigerants R600a and R290, which have a GWP (global warming potential) value of 3. This means that they comply with the new European F-gas Regulation. Furthermore, they are particularly quiet during operation, ensuring a pleasant work environment.

BINDER ICH light modules in two versions

The new ICH light modules are available in two functional versions with and without light-dose control (LQC). In both cases, the light is controlled via the device controller as the user interface.

ICH light module without light-dose control

The ICH light module is connected to the climate chamber via a data cable. This makes it possible to control the irradiation duration of the illumination cassettes individually with a time-segment program via the program controller of the climate chamber.

ICH LQC light module with light-dose control

The ICH LQC light module also contains two spherical light sensors. The VIS sensor measures the illumination level of the visible light and the UVA sensor measures the irradiance level of the UVA light. Both sensors evaluate the light with a spherical characteristic, which is useful for three-dimensional test objects. The light dose must be increased by a factor of 1.5 for photostability tests on flat test objects, such as printed products.

The ICH LQC light module is also connected to the climate chamber via a data cable and the light control runs via the program controller. The light dose to be achieved for the two types of light is entered in the controller and the illumination cassettes are switched off individually once the dose has been reached.

Emission spectra of the illumination cassettes

The latest LED technology with spectral characteristics similar to sunlight is used in the white light cassette (VIS). The UVA range cannot be covered with current LED technology in accordance with ICH requirements, which is why special fluorescent tubes were used. The two illumination cassettes together reproduce the CIE-D65-like spectrum required by the ICH guideline perfectly.