#Product Trends

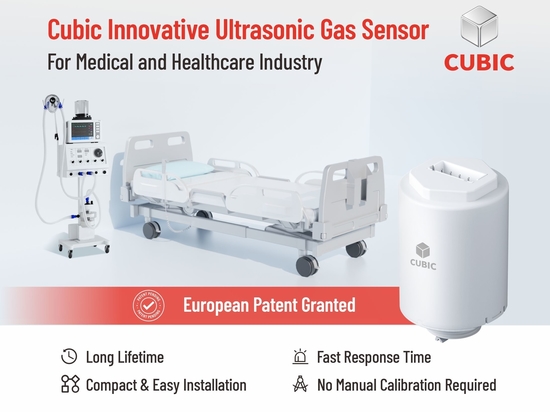

Cubic Gas Sensing Technologies for Medical Applications

Gas detection is a relatively mature field: there are many different gas sensing technologies on the market, all of which are with their own advantages and disadvantages.

With 20-year dedication to the development of gas sensing technologies, Cubic, an international manufacturer of advanced gas sensors and gas analyzers, has accumulated diverse mature sensing technology platforms including non-dispersive infrared (NDIR), tunable diode laser absorption spectroscopy (TDLAS), and ultrasonic technologies among others. From measuring gas concentration and air volume to monitoring pressure or flow rate in real-time, Cubic platforms can be applied to a wide range of medical industry needs.

NDIR gas sensors operate based on the NDIR principle that certain gases absorb infrared light at specific wavelengths. The detector captures and quantifies the infrared absorption at these wavelengths, and, through algorithmic analysis embedded in the software, it accurately assesses the concentration of the gas component. In medical applications, NDIR gas sensors emit infrared light through a sample chamber containing the target gas, including carbon dioxide (CO2), methane (CH4) and carbon monoxide (CO). The amount of absorbed infrared light correlates with the gas concentration, allowing for accurate gas measurements. Cubic has developed mainstream EtCO2 sensor module CM2201 to monitor the respiratory end tidal CO2 concentration and respiration rate, and DLCO sensor Gasboard-2050 to measure the diffusing capacity of carbon monoxide in the lungs.

TDLAS technology utilizes a “tunable” laser to emit light at precise wavelengths absorbed by specific gases. Within the context of medical applications, TDLAS gas sensors measure the intensity of the light absorption to accurately detect and quantify gases including oxygen (O2) with rapid response times and high reliability. Because of these advantages, TDLAS technology is a superior alternative to traditional paramagnetic oxygen detection methods in various medical applications. Cubic has designed oxygen sensor Gasboard-2510 for accurate oxygen concentration measurement.

Ultrasonic gas flow sensors adopt ultrasonic detecting technology and the principle of TOF (time of flight) to measure both the gas flow rate and gas composition in binary gases, which involves monitoring and analyzing the changes in acoustic waves as they travel through a gas mixture.

Ultrasonic gas flow sensors are typically equipped with a pair of ultrasonic transducers that serve dual functions, each capable of emitting and receiving ultrasonic signals. Positioned at distinct locations along the path of the gas flow, these transducers send ultrasonic pulses back and forth. The gas flow rate is calculated through the time difference of ultrasonic wave transmission.

Additionally, since the speed of sound differs among various gases, measurements of the speed at which an ultrasonic pulse travels through the gas can be used to measure the composition of the gas accurately.

In medical settings, ultrasonic gas flow sensors can be applied in devices such as spirometers and oxygen generators, where they provide precise measurements of both gas composition and flow rates. Cubic offers both Gasboard-7500 series and Gasboard-8500FS series oxygen gas sensor, providing options to accommodate diverse oxygen gas flow rate measurement demands. In addition, Cubic spirometry sensing solutions, Gasboard 7020 and Gasboard 7021, can provide rapid and accurate readout of critical respiratory parameters for hospital and residential spirometers.