#Product Trends

Blister Packaging Line equipped synchronous running Tube Feed System

Blister Packaging Line equipped synchronous running Tube Feed System

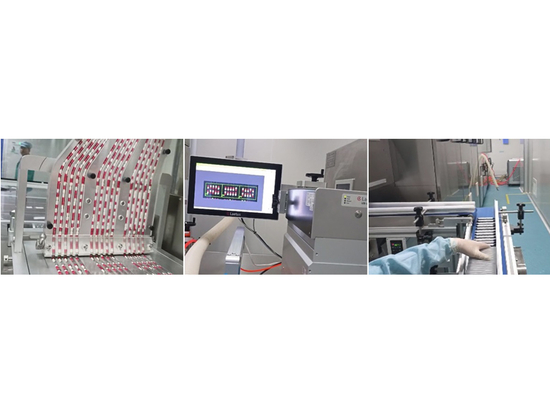

This Blister Packaging Line is combined with a continuous motion rotary-sealing Blister Machine and a continuous motion cartoning machine.

The Blister unit is equipped synchronous running Tube Feed System

This Blister Tube Feed System improves the performance and increases the productivity of your blister packaging production. It is suitable both for intermittent or continuous motion Blister Packaging Machine in medium or high speed.

This Tube Feeder can run in a reciprocating way on the rail, synchronously with the running webbing to fill the entire index (for continuous motion Blister Machine).

It can also fill the entire index of the Blister Machine at once while the webbing is stationary (for intermittent Blister Machine);

> Blister feeding begins by transferring the capsules or tablets into the hopper, they then exit the hopper via the linear vibratory conveyor.

> The combo structure consists of the upper tray, middle stray, and lower tray. It can fill the entire index of the Blister Machine at a time.

> The capsules or tablets are fed into the upper tray, the upper stray moves up and down together with vibration to assist capsules or tablets into the tubes.

> The upper tray is equipped with a sensor that can automatically monitor capsule or tablet level, when the level is low it will send a signal to the vibrator to convey more capsules or tablets.

> The middle tray controls the capsule, ensures only one capsule or tablet is passed to the lower tray at a time.

> Each tube in the lower tray is aligned with a blister pocket, when the webbing stops, the capsule or tablet is discharged into the pocket (for intermittent Blister Machine); synchronously with the running webbing to fill the entire index (for continuous motion Blister Machine).

After cutting, the blister cards are collected by the vacuum arm, and transferred to the cartoner; the faulty blister cards can be rejected automatically (optional).

The cartoner unit:

> In the cartoner unit, Inside the magazines the blister cards are counted when they free fall via the servo- motor, and are then held in position by the transfer belt.

> The Leaflet are isolated from the bottom from a pile magazine, then pulled off and folded. It can make the leaflet fold one to four folds according to customer’s demand.

> The rotary carton pick-up sucks the cartons from the carton magazine then places them in the carton conveyor chain.

> After actions of inserting blister cards and leaflets into cartons, embossing, and closing, the cartons were discharged automatically.