#Product Trends

Progressive Cavity Pumps More Than Double Capsule Filling Production in Pharmaceutical Processing

Automation Drives Results and Meets Specification Requirements

The pharmaceutical industry has seen a growing need for personalized medication. Modern medicine and treatments have improved. However, there are some patients who cannot take over-the-counter drugs. This is due to organ restrictions, allergies, stomach problems, personal preferences, more precise dosing, or limited access to medicines.

While one drug works for one person, it may not be as effective for someone else. Taking each person’s individual uniqueness into account, many doctors are writing personalized prescriptions to best treat their patients.

When a compounding pharmacy receives these requests, they formulate the individual prescriptions from scratch, ensuring consistency between drug formulations. These recipes are usually a mixture of medicine and oil, the latter serving as a fat source for better absorption. This blog will show how a compounding pharmacy upgraded to an automated capsule filling solution (robot and a progressive cavity pump) that enabled them to increase production and improve accuracy.

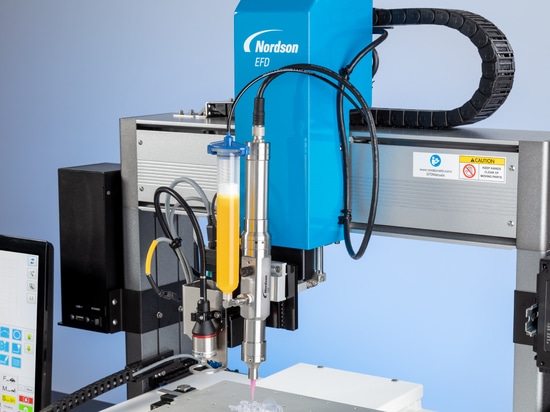

Previous Process: The pharmacy used a machine to pour a thin mixture of hormone, vitamin, and olive oil into small capsule parts. These parts would be sealed with the bigger capsule part later on. (See Figure 1)

While this process was effective, their 30cc syringe barrels would only yield 60 capsules before having to swap out for a new syringe and reset the dispenser. This was the only size of syringe barrel compatible with the fluid dispenser they were using; it created unnecessary downtime and slowed production.

Fluid Used: Low-viscosity mixture of hormone, vitamin, and olive oil

Application Requirements:

• Capsules must have a filled weight of 0.4 g and can only deviate by ±5%

• Faster production with less downtime

• Ability to fill more capsules per fluid reservoir (syringe barrel)

• Must be compatible with varying viscosities between recipes

Results

When organizations want to improve production and accuracy, automation offers a path forward. After evaluating their current production method, Nordson EFD determined that the compounding pharmacy’s process could be easily configured with a robot. Technical services recommended the EV series automated dispensing system, which was an upgrade from benchtop dispensing. The advantage a fully automated system had over the existing manual process was that it eliminated human error, which can result in inconsistent batches. And, with the requirements to have a filled weight of 0.4 g that could only deviate by ±5%, having a robot monitoring everything on the backend when precisely filling each capsule half proved extremely beneficial.

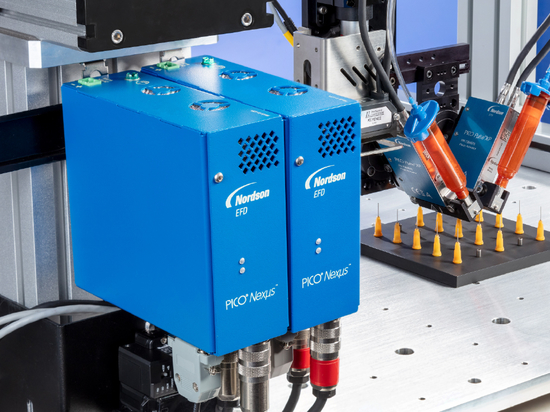

The next key technology recommendation was the Nordson EFD 797PCP progressive cavity pump, which accurately dispensed the mixture within the ±5% accuracy requirements. The progressive cavity pump provides continuous volumetric dispensing independent of fluid viscosity or changes in viscosity over time. That ensures reliable, repeatable control, which is essential for medical applications. The pump could also be easily cleaned with pure olive oil in between medicine recipes as well.

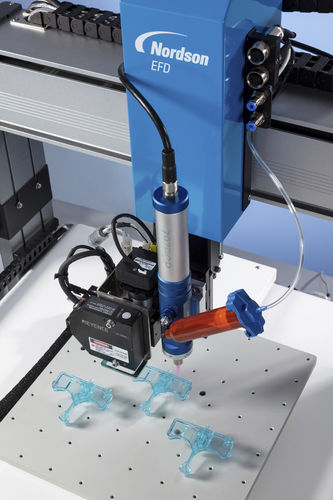

In addition, the Nordson EFD Optimum line provided some useful components that complemented the automated setup. The 70cc Optimum syringe barrel allowed the 797PCP progressive cavity pump to dispense into 200 capsule halves before requiring a swap for a new syringe barrel. This was a huge jump from the maximum 60 capsule halves they were dispensing into prior with this setup. The larger syringe size helped more than double their production and reduced downtime.

Nordson EFD’s beige SmoothFlow pistons are loose-fitting pistons used with air-entrapped fluids. These worked well since air bubbles are common in the mixture and the air has a place to escape with this piston. The piston also features a wiper design that reduces the amount of fluid waste in a syringe, which is vital when working with expensive fluids. Lastly, our 14ga olive tapered dispensing tip was beneficial in this application because its larger gauge allowed particles to easily flow through without clogging the tip.

Conclusion

Overall, the complete Nordson EFD setup increased the pharmacy’s production rate, reduced downtime, and ensured that everything met their exacting specifications. In the future, Nordson EFD’s stainless steel PCP pump would certainly be a value add for the company’s capsule filling application. Having a corrosion resistant material helps with the longevity of the pump, a production advantage for the growing compounding pharmacy market.

If you would like to discuss your next pharma application with an experienced fluid dispensing expert, don’t hesitate to email us at info@nordsonefd.com.