#Product Trends

Principle of How to Precisely Control CO2 Concentration in CO2 Incubator

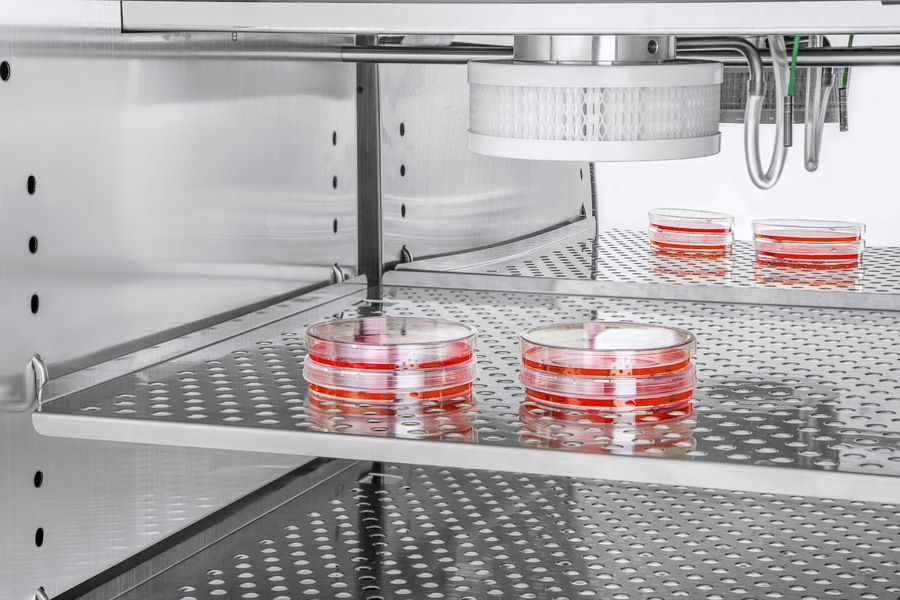

The carbon dioxide (henceforth referred to as CO2) incubator is laboratory equipment for cell culture.

To provide the most ideal environment for cell growth, the prevention of contamination is not the sole focus during the process, but also the precise control of temperature, relative humidity and CO2 concentration in the incubator.

This article explains the principle of how to control the concentration of CO2 in the incubator.

As we all know, the optimum pH for cell growth is mostly 7.0-7.7. To maintain a stable pH, usually a buffer that uses CO2 -bicarbonate as its base will be added to the growth medium. In the process of cell culture, if the concentration of the carbon dioxide in the incubator be controlled precisely, it will facilitate the stability of the medium’s pH. Given the precise control of CO2 concentration is of significance, how does the incubator monitor the change in the concentration of carbon dioxide?

As the technology develops, the CO2 sensors can effectively monitor the change in CO2 concentration in the incubator. Currently, the methods used for sensors to measure CO2 concentration mainly include thermal conductivity (TC) and infrared (IR).

TC sensors

TC sensors measure the concentration of CO2 by detecting the difference between two resistances in air. The TC sensor consists of a pair of resistors: A, which is placed in a “sealed” environment, and B, which is exposed to the environment of culture. The resistance between the two resistors will shift with the concentration of CO2 so that it could be regulated.

One of the drawbacks of TC sensors is that the accuracy of the sensor is highly dependent on the temperature and relative humidity of the incubator, which will greatly fluctuate if the incubator door opens and closes frequently, and therefore affects the accuracy of TC sensors. This system is not suitable when the precision of conditioning collided with the need for frequent opening of the incubator door.

IR CO2 sensors

IR sensors detect CO2 levels through an optical sensor which includes an infrared emitter and a sensor. When the CO2 in the incubator absorbs part of the infrared emitted by the emitter, the sensor can detect the reduction of the infrared, which corresponds to the level of the CO2 in the incubator, and therefore obtains its concentration.

Consider that the IR system determines the concentration of CO2 via the reduction of infrared rays, which it can partly reflect or absorb by the amount of particulate in the incubator, therefore the IR system is more sensitive for the detection and will not be affected by temperature and humidity. Thus, it is more suitable to be adopted by incubators equipped with HEPA high-efficiency air filters in their air inlets intakes.

And The RWD CO2 incubators uses the infrared (IR) sensor to achieve precision control of CO2 concentration and therefore a more appropriate environment is provided for cell culture.

Highlights of RWD CO2 Incubator

High-temperature resistant IR CO2 sensor enables precise monitoring of CO2 concentration.

A six-sided air jacket heating system ensures fast heating.

140℃ dry heat sterilization methods with in-chamber HEPA filter enable inner chamber purity.

Automatic data record of 7 days curve display for fast and convenient data recording.