#Product Trends

Basic Introduction of Guide Wire for Beginners

The guide wire is composed of inner and outer parts. The interior of the guide wire, is equipped with a continuous and hard steel wire core. According to the needs, the core material can be stainless steel wire, Nitinol memory alloy, or both. The fro

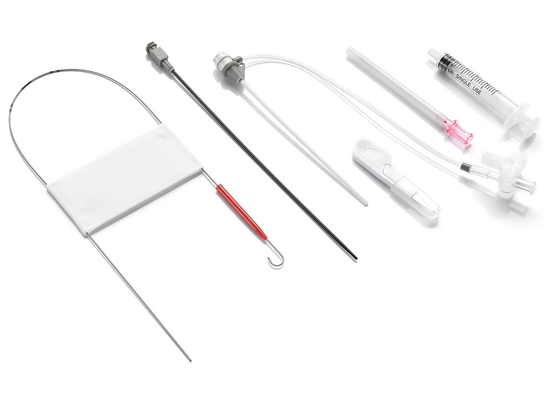

The interventional operation generally needs to be operated under medical imaging equipment such as digital subtraction angiography machine, CT positioning and B-type ultrasound instrument. Puncture needles, catheter sheaths, guide wire, various catheters, balloons and stents are commonly used instruments. Here we mainly introduce the guide wire.

The composition of guide wires

The guide wire is composed of inner and outer parts. The interior of the guide wire, is equipped with a continuous and hard steel wire core. According to the needs, the core material can be stainless steel wire, Nitinol memory alloy, or both. The front end of the steel core gradually becomes thinner. The tip of the very thin steel wire core is welded with the end of the spring, and then the end of the steel wire core is welded with the end of the spring and polished smoothly. The outer layer of the traditional guide wire is made of high-quality stainless steel wire wound on the spring rotating machine. The steel wire shall be smooth, tough and elastic, and the winding must be uniform and tight, neatly arranged and consistent in looseness and density. The spring shall be able to withstand repeated bending and will not break under the action of a certain force. In recent years, there are fewer and fewer bare metal guide wires coated with springs. Instead, polymer materials with better histocompatibility and blood compatibility (mainly polyurethane or PTFE and fluorine materials) are coated on the surface of metal wires. This method of passing through polymer metal wire can not only replace the hard contact effect of the previous spring coil on the inner wall of the lumen, but also greatly reduce the surface friction of the guide wire. It can also enhance the visibility of the whole guide wire operation process by coating stripes on the polymer surface or adding developing materials (especially polyurethane materials) into the polymer. This is particularly prominent in zebra guide wire coated with stripes, polymer PTFE coated guide wire and polyurethane coated guide wire. This surface coating method has been more and more used in the design and manufacture of guide wires. The hydrophilic coating can also be added to the surface of this kind of guide wire to further reduce the friction of the guide wire surface.

The clinical performance of guide wire

The clinical performance of guide wire products is mainly judged by the following aspects: support force (the force of vertical guide wire force to bend the guide wire), flexibility (the ability of the guide wire to change with the degree of vascular bending), tracking (the ability of the guide wire to walk along with the vascular anatomical structure), torsion (the ability to transmit torque from the proximal end of the guide wire to the tip of the guide wire), Tactile feedback (feel the contact of the head end of the guide wire with the object and the feedback on the properties of the object from the proximal end of the guide wire), visibility (the guide wire does not transmit linearly, which is conducive to the positioning of the guide wire in the body).

Looking for a guide wire supplier?

SCW Medicath Ltd. is one of the earliest manufacturers of guide wire in China. It can produce all kinds of length (from 45cm to 4.5m), all kinds of diameters (0.014 " to 0.038"), and all kinds of materials or coatings (stainless steel, nitinol, PU coating, PTFE coating, hydrophilic coating, zebra guide wire, etc.), all kinds of functions or shapes (straight head, elbow, contrast guide wire, renal puncture guide wire, etc.).

SCW MEDICATH LTD, established in 1996 and headquartered in Shenzhen, is the first factory to develop and manufacture Central Venous Catheters, Blood pressure Transducer and many other products in China. As a professional medical manufacturer, SCW has specialized in the field of Intervention, Anesthesiology & Critical Care, Obstetrics & Gynecology, Urology, Medical Imaging, Orthopedics and other high-value medical consumables. At present, SCW has more than 60 domestic registered products, and more than 30 CE certified products. SCW is certified by ISO13485 Quality System Certificate, and CE Certificate. SCW products are sold across China, and exported to more than 80 countries and regions.

For any more information about guide wires, please do not hesitate to contact us.