#Product Trends

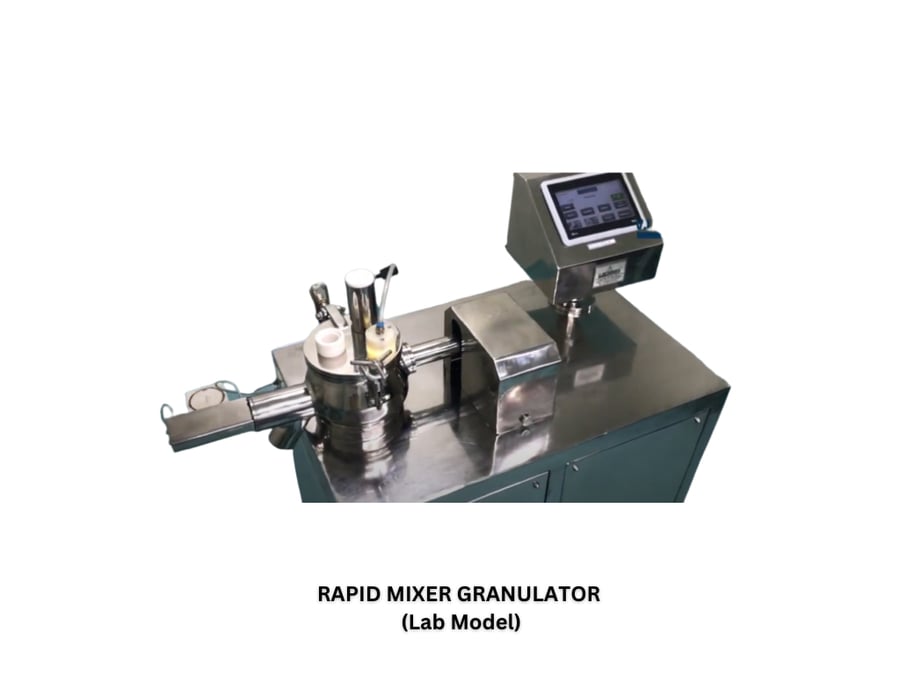

ABOUT RAPID MIXER GRANULATOR

Granulation is the process of forming grains or granules from a powdery or solid substances, producing granular material. Typically granulation involves agglomeration of fine particles into larger granules, typically of size range between 0.2 and 0.4 depending on their subsequent use.

Reasons for Granulation

To avoid powder segregation

To enhance flow of powder

To produce uniform mixture

To produce dust free formulations

To eliminate poor content uniformity

To improve compaction characteristics of mix

Granulation From Fine Powder:

The granulation process combines one or more powder particles and form granule that will allow tableting to be within required limits.

It is the process of collecting particles together by creating bonds between them.

Bonds are formed by compression or by using binding agents.

Granulation is extensively used in pharmaceutical industry for manufacturing of tablets and pallets.

Granulation is carried out for various reasons, one which is to prevent the segregation of the constituents of powder mix.

Segregation is due to the differences in the size or density of the components of the mix.

Normally, the smaller and/or denser particles tends to concentrate at the base of the container with the larger and/or less dense ones on the top. An ideal granulation will contain all the constituents of the mix in the correct proportion in each granule and segregation of granules will not occur.

Many powder because of their small size, irregular shape or surface characteristics, are cohesive and do not flow well.

Granules produced from such cohesive system will be larger and more isodiametric (roughly spherical). Both factors contributing to improved properties.

Some powders are difficult to compact even if a readily compactable adhesive is including in the mix, but granules of the same powders are often more easily compacted.

This is associated with the distribution of the adhesive within the granule and is a function of the method employed to produce the granules.

Three types of granulation technologies are used

Wet granulation

Dry granulation

Direct Compression