#Industry News

How to manage air treatment in sterilization areas?

Sterilization involves cleaning, disinfecting, and storing medical instruments after medical procedures, to eliminate pathogens and ensure they are safe to use for the next procedure.

It is equally important to maintain clean air in these areas to prevent contamination, protect the integrity of the sterilization process and ensure the highest levels of hygiene in the hospital.

Different areas in sterilization

1. Washing area (or dirty area): Where used instruments are cleaned and decontaminated in ultrasonic cleaners, washers-disinfectors, and formaldehyde sinks. As it is the first step of the cleaning process, negative pressure is maintained to prevent contaminated particles from spreading to the other areas.

2. Preparation and conditioning room: Instruments are inspected and packaged. A positive pressure must be maintained (generally +20 Pa) to prevent contaminants from backflowing.

3. Sterilization zone / Autoclave: Instruments are treated in steam autoclaves at high temperatures. Neutral pressure avoids leaks and ensures controlled conditions.

4. Sterile storage: Instruments are stored safely before their next use. Positive pressure protects against external contamination.

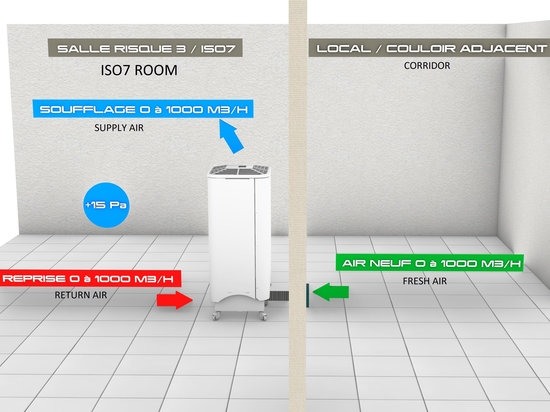

In these areas, the cleanness standard is generally ISO 8. In some specific cases and zones (ex: some conditioning areas), ISO 7 may sometimes be required. These standards must absolutely be studied in order to prevent contamination and maintain safety across sterilization processes.

Additional rooms may also be required, depending on the project. For instance, depending on the type of doors on the autoclaves (single or double access), there may have to include additional airlocks or other chambers. Properly assessing the pressure cascade is essential to ensure an optimized airflow and contamination control throughout the entire process.

With our expertise, we design tailored air treatment solutions for sterilization areas. Our compact and hygienic Clinicair systems are designed for optimal integration, ensuring they meet the specific needs of these critical services.

For a customized approach to your sterilization area projects, contact our team.